Researchers throughout the US have designed an electrochemical path to have an effect on and decarbonise cement manufacturing. The tactic, which generates calcium carbonate with out relying on limestone decomposition, must be comparatively simple to mix into current industrial manufacturing strategies.

After the vitality sector, cement manufacturing is the second largest industrial contributor of worldwide greenhouse gas emissions, primarily because of limestone calcination – a course of that releases big portions of carbon dioxide. No matter in depth evaluation, standard cement methods have remained largely unchanged. Current efforts to decarbonise the commerce by incorporating waste provides, comparable to coal fly ash or blast furnace slag from typical metallic manufacturing vegetation, into Portland cement face limitations because of effectivity and supply constraints. Furthermore, such provides can solely trade decrease than half of the Portland cement utilized in concrete, leaving the commerce carefully reliant on carbon-intensive practices.

Now, a collaboration between scientists at Lawrence Livermore Nationwide Laboratory (LLNL) and Northwestern Faculty has put forward a method they’re saying is ready to attaining gigaton-scale carbon reductions. Their methodology accelerates the weathering of calcium silicates sourced from basalt, recycled concrete and industrial waste, then makes use of carbon dioxide to provide calcium carbonate, eliminating the need for limestone decomposition.

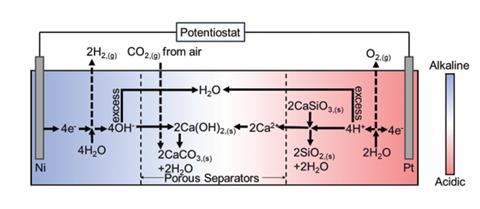

‘We use an electrochemical cell to actively seize carbon dioxide so that our calcium carbonate feedstock for cement manufacturing is carbon unfavorable,’ explains LLNL group member Wenxin Zhang. The tactic works by making a pH gradient contained in the electrochemical cell, which leaches calcium ions from the silicates. These ions then react with atmospheric carbon dioxide or captured carbon dioxide, to provide calcium carbonate and amorphous silica.

‘It is applicable with the usual cement manufacturing vegetation with out the need to change the vegetation because of our course of nonetheless provides a calcium carbonate,’ says Zhang. ‘Calcium carbonate along with the amorphous silica might also act as so-called supplementary cementitious provides by furthermore mixing these electrochemical merchandise with cement, the strategy might finally flip into extra carbon unfavorable, because of we moreover straight seize and retailer carbon.’

Circularity is a major focus of the study and Zhang highlights that the electrochemical course of works at room temperature, ‘so it’s capable of using renewable electrical power sources which could be intermittent because of it doesn’t require heating’.

Furthermore, the strategy moreover generates helpful co-products, along with inexperienced hydrogen and oxygen. These might trade fossil fuels as a heat provide for calcium carbonate decomposition and permit oxy-fuel combustion, respectively. The captured carbon dioxide has extra potential for conversion into calcium bicarbonate to mitigate ocean acidification.

‘The circularity is developed in some very attention-grabbing strategies; the [researchers] have clearly thought quite lots about course of integration and synergies that will enhance the inexperienced credentials of their course of,’ says John Provis, an expert in cement strategies, from the Paul Scherrer Institute in Switzerland. ‘It does in spite of everything rely upon having a decarbonised provide {{of electrical}} vitality, however when this can be achieved, they recommend quite a lot of in all probability viable valorisation pathways for the fully completely different supplies streams they’re producing.’

Previous its environmental benefits, the know-how provides potential monetary benefits. It reduces enter costs by relying on plentiful raw provides and renewable vitality, whereas minimising retrofitting requirements for current vegetation. Furthermore, it might generate earnings from byproducts and carbon credit score.

To find the potential for scaling up its methodology, the group plans to conduct location-specific analyses. This would possibly provide further smart and smart suggestions for industrial companies to implement the strategy ultimately.